SUPERABSORBENT NONWOVENS FOR MEDICAL APPLICATIONS

Superabsorbent Fabrics for Medical Consumables

We manufacture a wide range of truly superabsorbent fabrics for use in medical products and consumables, including: foam, island and superabsorbent medical/wound dressings; burns dressings, bandages and blankets; spill capture mats; and use in diagnostic kits, disposal and transportation thereof.

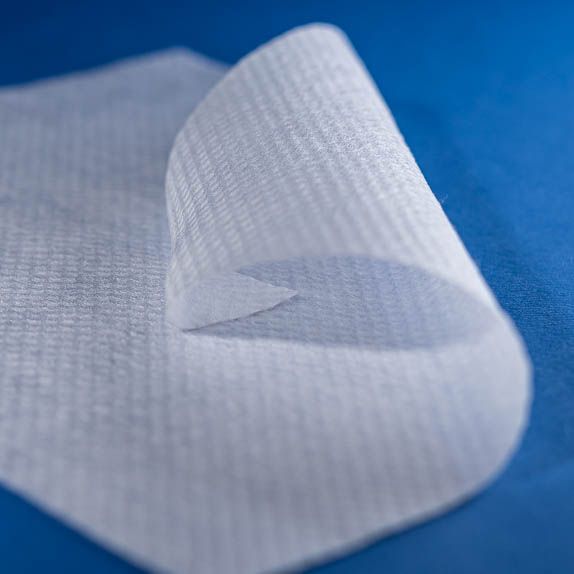

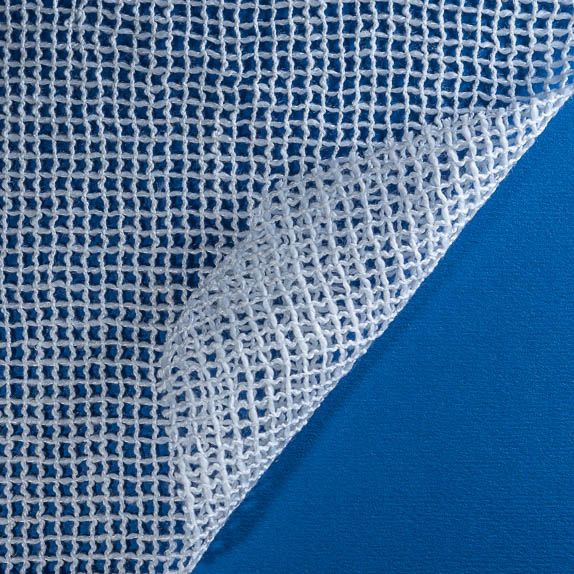

Our Superabsorbent Fabrics – all containing our Super Absorbent Fibre (SAF™) – provide a solution that is highly absorbent, soft, conformable and that doesn’t need edge sealing.

We can achieve superabsorbent fabrics with up to 60% SAF™ and have a catalogue of fabrics readily available to sample – you can browse some of these below.

Bespoke fabrics can also be manufactured if required.

So, what is SAF™?

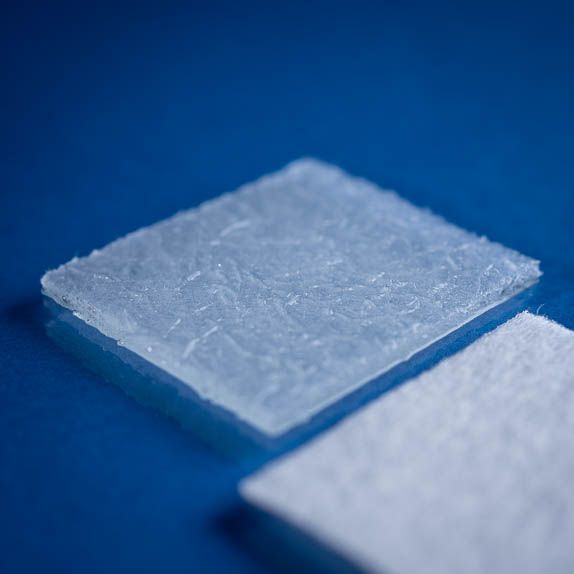

SAF™ is a highly technical, soft, staple fibre, that absorbs significant amounts quickly. In fact, it can take in up to two

hundred times its own weight in water, even under load!! It also provides excellent levels of containment and retention, which can be hugely beneficial in a wide range of applications. We blend SAF™ with a wide range of other fibre types, to produce high performing superabsorbent fabrics and yarns that are all Powered by SAFology™.

Medical Samples: Superabsorbent Nonwoven Fabrics

Refine your search by application to discover the perfect absorbent product for your needs.

Need guidance or a custom solution?

Need expert help selecting an absorbent solution? Email us now! Our team of SAFologists will swiftly respond to discuss your needs and guide you to the right fibre, fabric or yarn. From concept to launch, we’re here to solve your super absorbency challenges. Don’t wait – contact us today!